Who We Are

Established in 2006 in Hangzhou—China's textile epicenter. We span 30,000 sqm with two factories and two trading arms for seamless production‑to‑export.

Scale for Reliability

700+ circular and 72+ warp knitting machines deliver sport, active, leisure and yoga fabrics (e.g., Polyester, nylon, modal, tencel, viscous, cotton and blends) at 12-18k+ tons per container in volumes, shortening delays up to 20%.

Proven Partnerships

Trusted by 20+ Chinese and Global brands, ensuring consistent quality yarns, knitting and dyeing to meet buyers standards like Oeko‑Tex.

Integrated Edge

Full‑chain control (Fiber selection, yarn, knits, greige finished fabrics) reduces costs upto 15% and speeds delivery to Vietnam, Cambodia, Egypt, Jordan and more.

At a Glance

- Founded: 2006 — Hangzhou, China

- Footprint: 30,000 sqm over two factories

- Machines: 772+ knitting units (700+ circular, 72+ warp)

- Markets: USA, Europe, China, Japan, Turkey, Vietnam, Bangladesh, Egypt, India

Mission

Leading Hangzhou's knitted fabrics—ready to be your sourcing one stop solution. Contact for samples/quotes.

Vertical Integration

As a leading integrated knitted fabric mill in Hangzhou, H Power is uniquely positioned to deliver matched scale, speed, and quality.

Our Capabilities

Knitted Fabrics

Weft Knits, Warp knits; Single/Double; (Sand, Sand wash) Scuba, Rib; Terry/French Terry; Fleece, Polar, Peaching and Raising.

Yarn Production

Compact Siro, Vortex — Greige & Dyed; blended series, Finished Fabric supplier.

Quality & Compliance

Oeko‑Tex alignment and consistent dyeing standards as per brands performance requirements.

Integrated Supply

Yarn‑to‑knit control for speedy delivery and cost savings.

Global Logistics

Delivery to US, EU, China, Turkey, Vietnam, Bangladesh, Egypt, India and Cambodia.

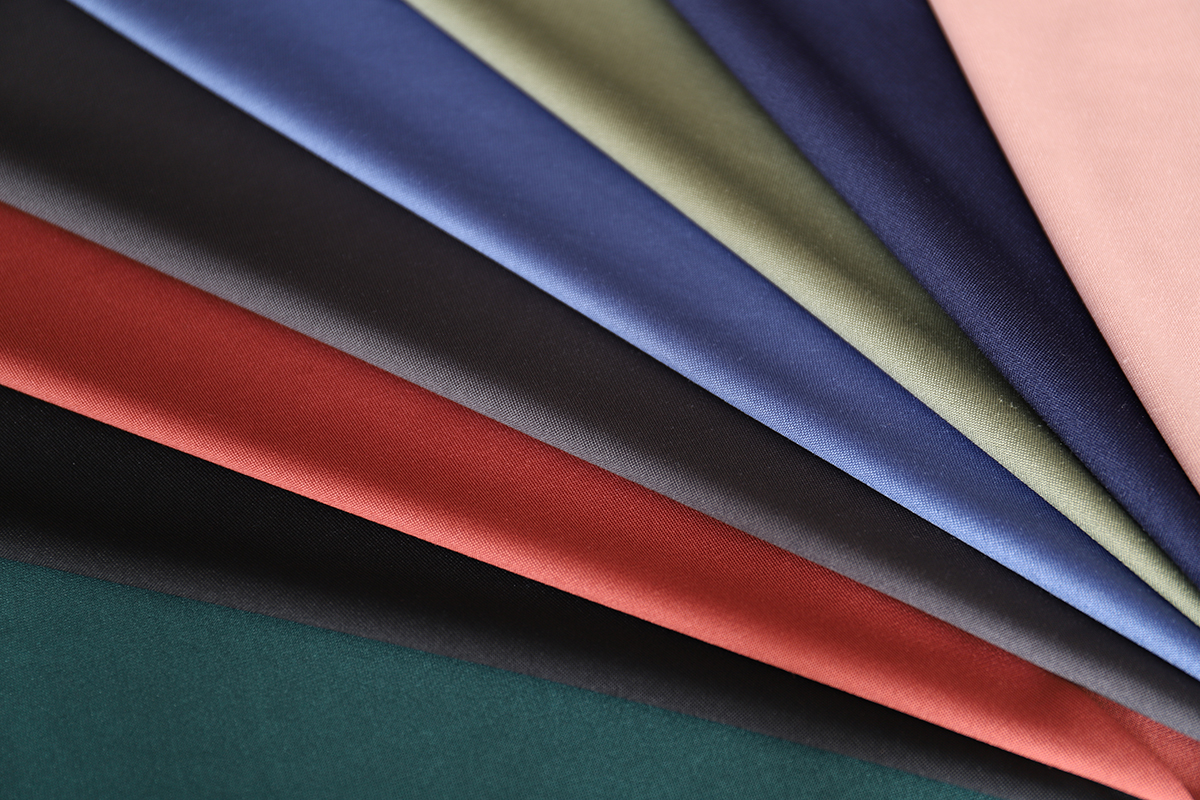

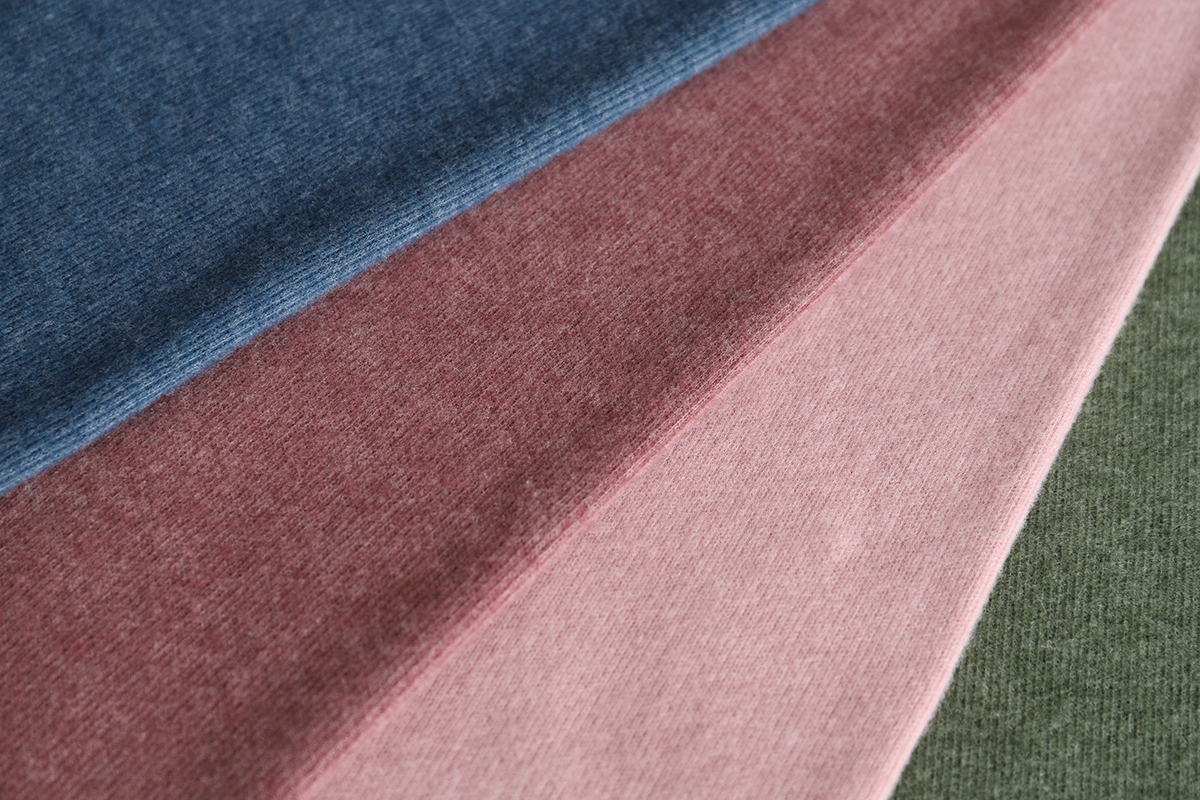

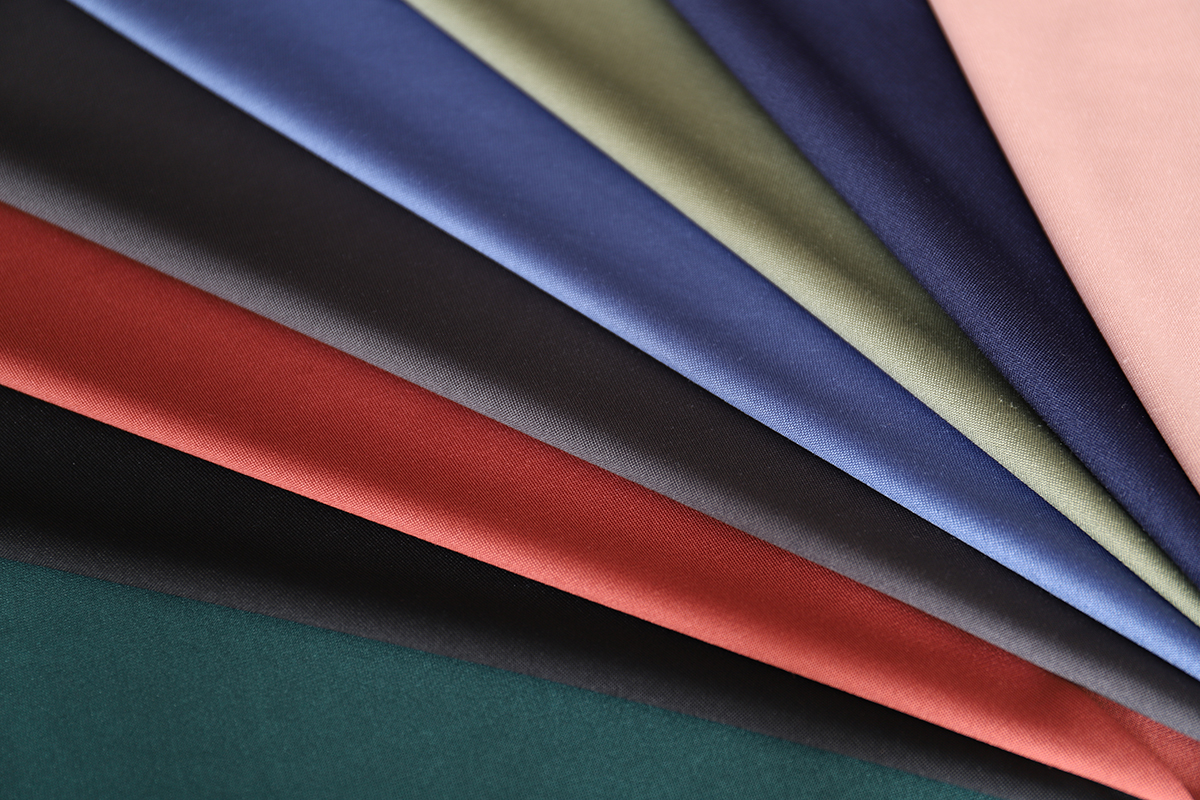

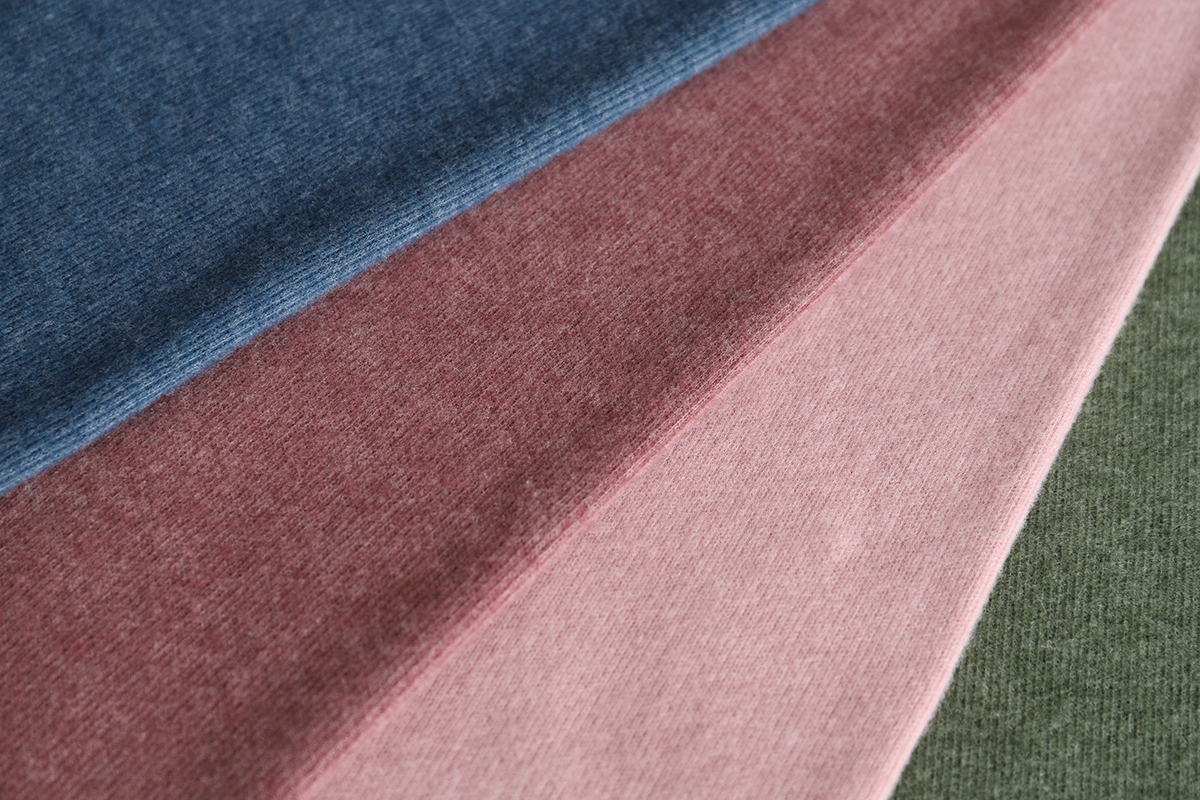

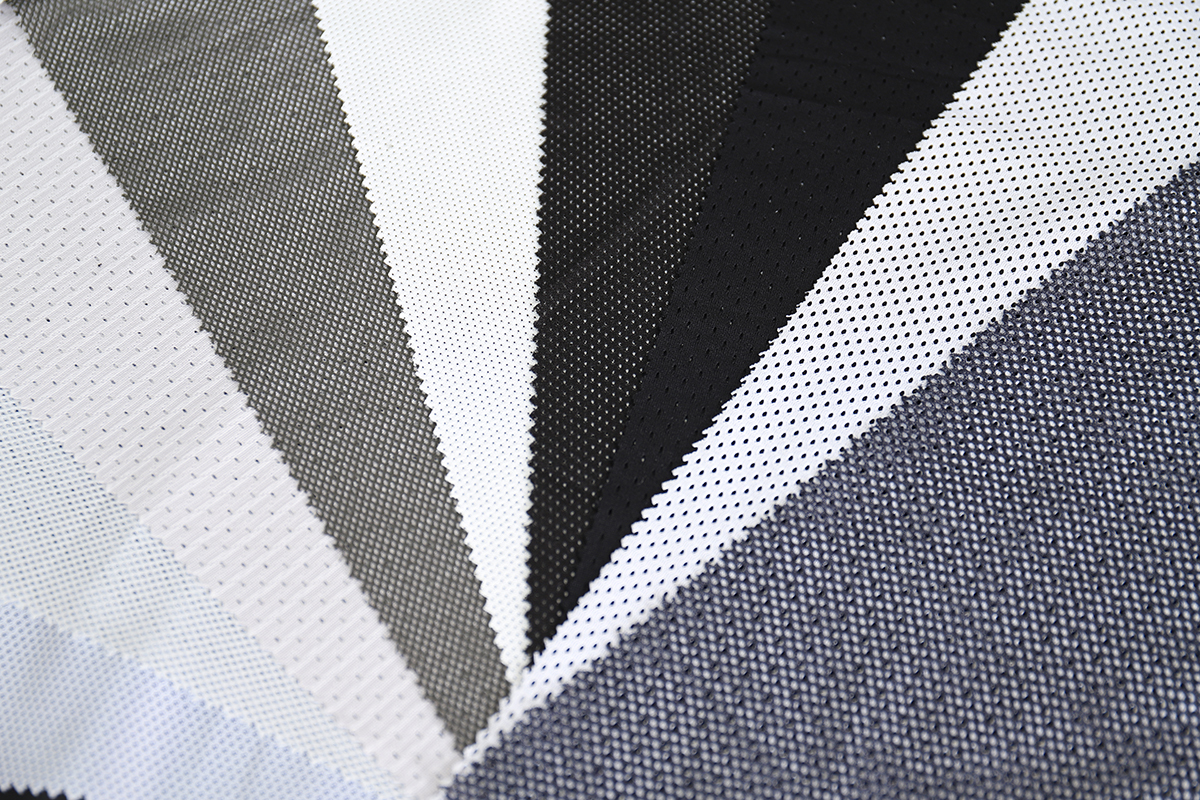

Products

Sport and leisure fabrics, supported by a full yarn portfolio and integrated production.

Premium Fabrics

Featured Apparel

-BUeOM1c_.png)

-BS7zOZ0k.png)

-BPTMGuk-.png)

-h1HboQ2t.jpg)

-BpXDdJAw.png)

-CAIda3Um.png)

Yarn Sales Department

Premium quality yarns engineered for exceptional fabric production

-1Ms14NJZ.jpg)

Greige Yarn

- Cotton, Polyester, Rayon, Acrylic, Cellulose fiber

- Blended & Differentiated Series

- Ring Spun, MVS, Siro Compact, Combed Yarns

Dyed Yarn

- Dope Dyed, Polyester, Cotton, Modal, Tencel, Viscous, Rayon, Acrylic.

- Heathers yarns, Slub yarn, Space dye yarn, etc.

Main Products — Knitted Fabrics

Industry-leading fabric solutions for global fashion and performance brands

Weft & Warp Knits

Nylon/Polyester/Spandex warp knits for sport and performance.

Single & Double Knits

Lightweight modal blends to dense interlock/rib structures.

Rib & Verigated Ribs

Elastic edges and cuffs with integrated dyeing for one‑stop efficiency.

Terry & French Terry

Looped textures for activewear; minimized defects in high‑volume runs.

Fleece & Polar

Soft‑hand feel options for leisurewear scaling to 20k kg/week.

Printing (Phase 2)

Custom designs without tooling costs (upcoming phase).

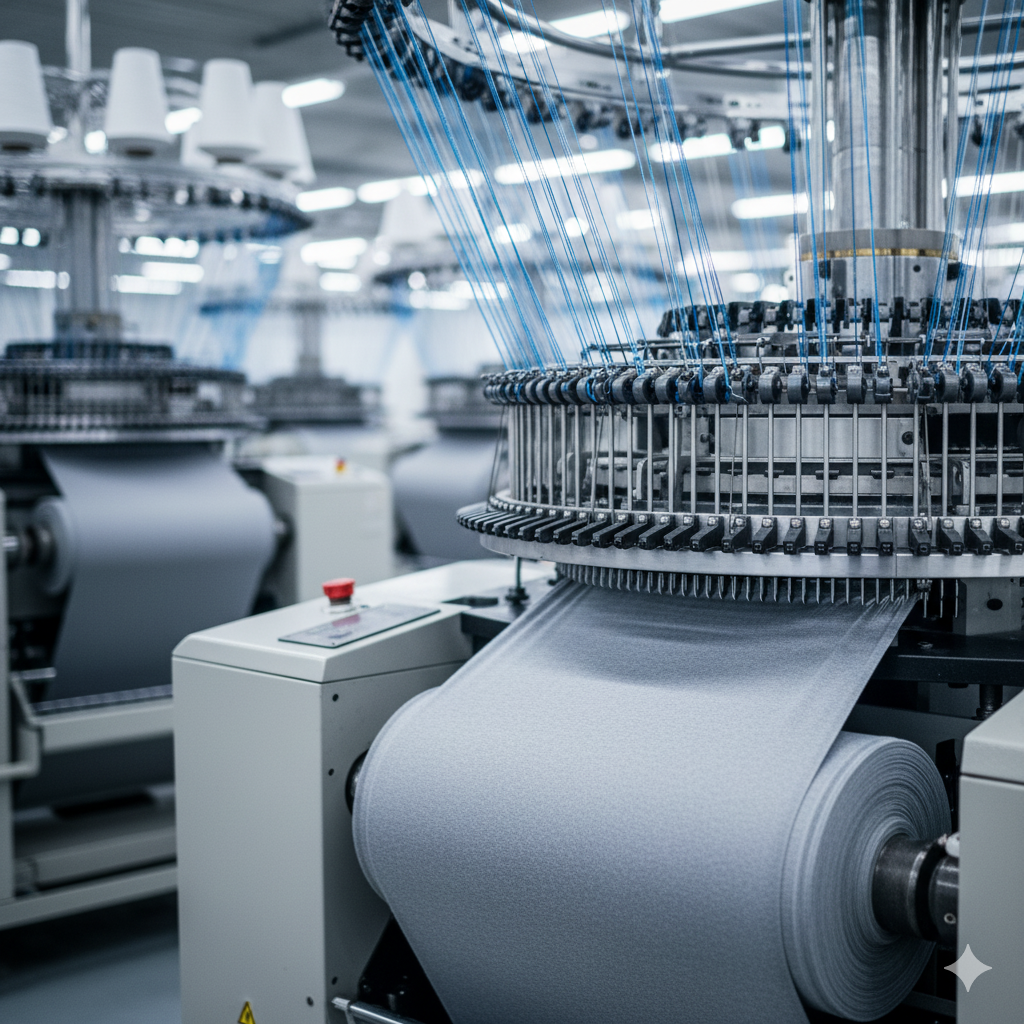

Our Equipment

With 700+ circular knitting machines across two 30,000 sqm factories, we deliver consistent greige/knitted fabrics at container scale.

Built for Scalable, Reliable Production

Open Width

150 units (34/38", 28–40G). High‑speed for flat knits/jersey, ~3k kg/day output—ideal for bulk sportswear without seams.

Single Knitting

150 units (30/34/38", 24–34G). Versatile for lightweight modal fabrics; supports 5x order spikes seamlessly.

Double Knitting

150 units (30/34/38", 18–38G). Dense interlock/rib structures; quality for leisurewear scaling to 20k kg/week.

French Terry

150 units (30/34", 18–24G). Looped textures for activewear; minimizes defects in high‑volume runs.

Jacquard

50 units (34", 18–28G). Patterned knits for branded designs—custom without tooling costs.

Rib

50 units (34/38", 18G). Elastic edges/cuffs with integrated dyeing for one‑stop efficiency.

Global Presence

Integrated production in Hangzhou with export reach across major manufacturing hubs and markets.

Our Partners & Certifications

Trusted by 20+ global brands with world-class certifications ensuring quality and sustainability.

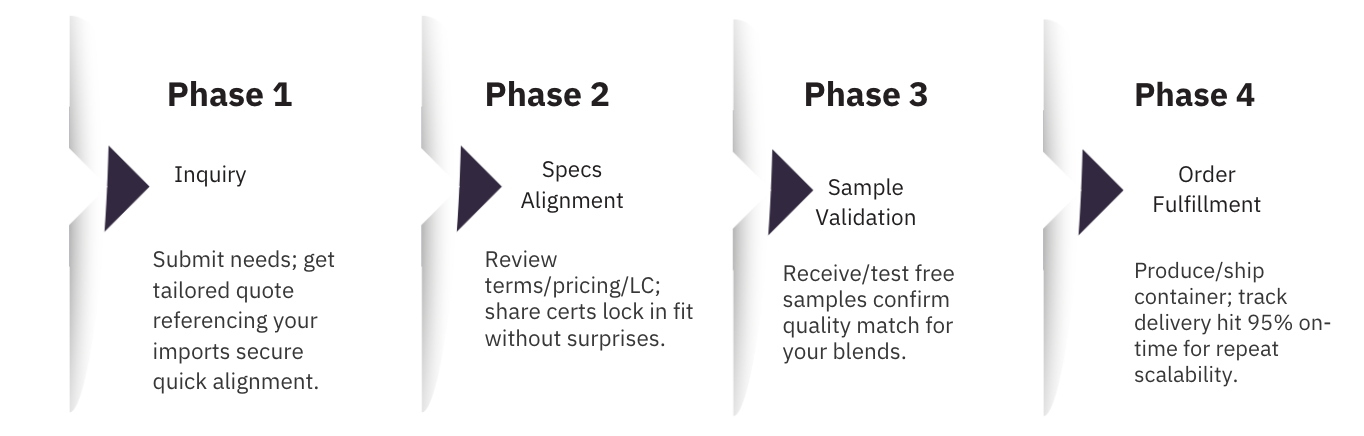

Get in touch

Email: info@hpowertextiles.com

Address:

HPower Textile Co Ltd,

Qunli Village, Guali Town,

Xiaoshan District, Hangzhou City,

Zhejiang Province, China 311241

Request Samples

Share your target blend, finish, GSM, and color requirements. We'll send free samples for validation.

- Blend & fiber (e.g., modal/cotton, polyester/spandex)

- Construction (single/double, rib, terry, jacquard)

- GSM range and finish (raising/fleece)

- Certifications (e.g., Oeko‑Tex)

-Dl2OF6qg.png)